technology and solutions

Digital Twin Technology

digital twin technology

Virtual Machine Simulation That Accelerates Engineering and Reduces Downtime

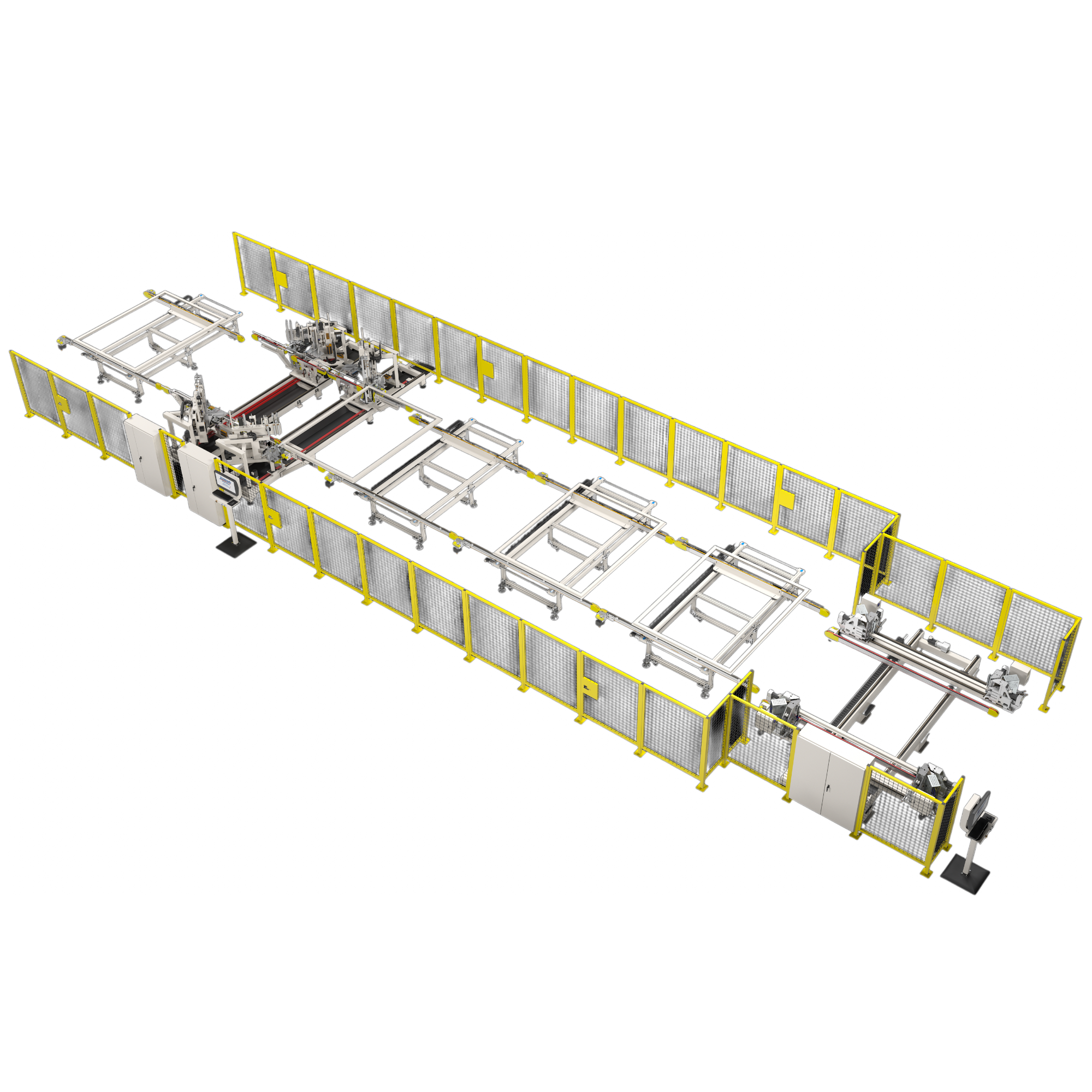

Joseph Machine leverages advanced digital twin technology to simulate, commission, and optimize machine performance in a fully virtual environment. Hosted in a real-time NVIDIA-powered simulation platform, our digital twin systems allow us to test and improve machines before they ever hit the production floor.

How It Works

- A complete digital replica of your machine runs actual PLC code in a simulated environment.

- Mechanical sequences, timing, and interlocks are tested against real-world conditions.

- Engineers optimize performance and correct logic issues before physical commissioning begins.

- Existing machines can also be virtually updated or reprogrammed to reduce on-site service time.

Benefits of the Joseph Digital Twin System

Faster Lead Times

Commissioning begins in the virtual world — not your factory floor.

Cycle Time Optimization

Get maximum throughput dialed in before shipping.

Remote Programming Updates

Changes can be validated and deployed with minimal downtime.

Service Efficiency

Simulate bugs or maintenance issues without taking production offline.

Used For:

- All custom-configured and multi-track systems

- jFlex CNC lines

- Multi-profile extrusion fabrication

- Machine upgrades and logic rework