webinars & events

Upcoming tradeshows and webinars

Joseph Machine Company Accelerates Innovation with Digital Twin Technology

Semi-automatic vs. automatic fabrication: What’s right for your fenestration production line (and why)?

Justifying lineal processing automation: Labor savings are just the tip of the iceberg

learning center

Answer your questions about fabricating lineal extrusions

Joseph Machine Company Accelerates Innovation with Digital Twin Technology

about us

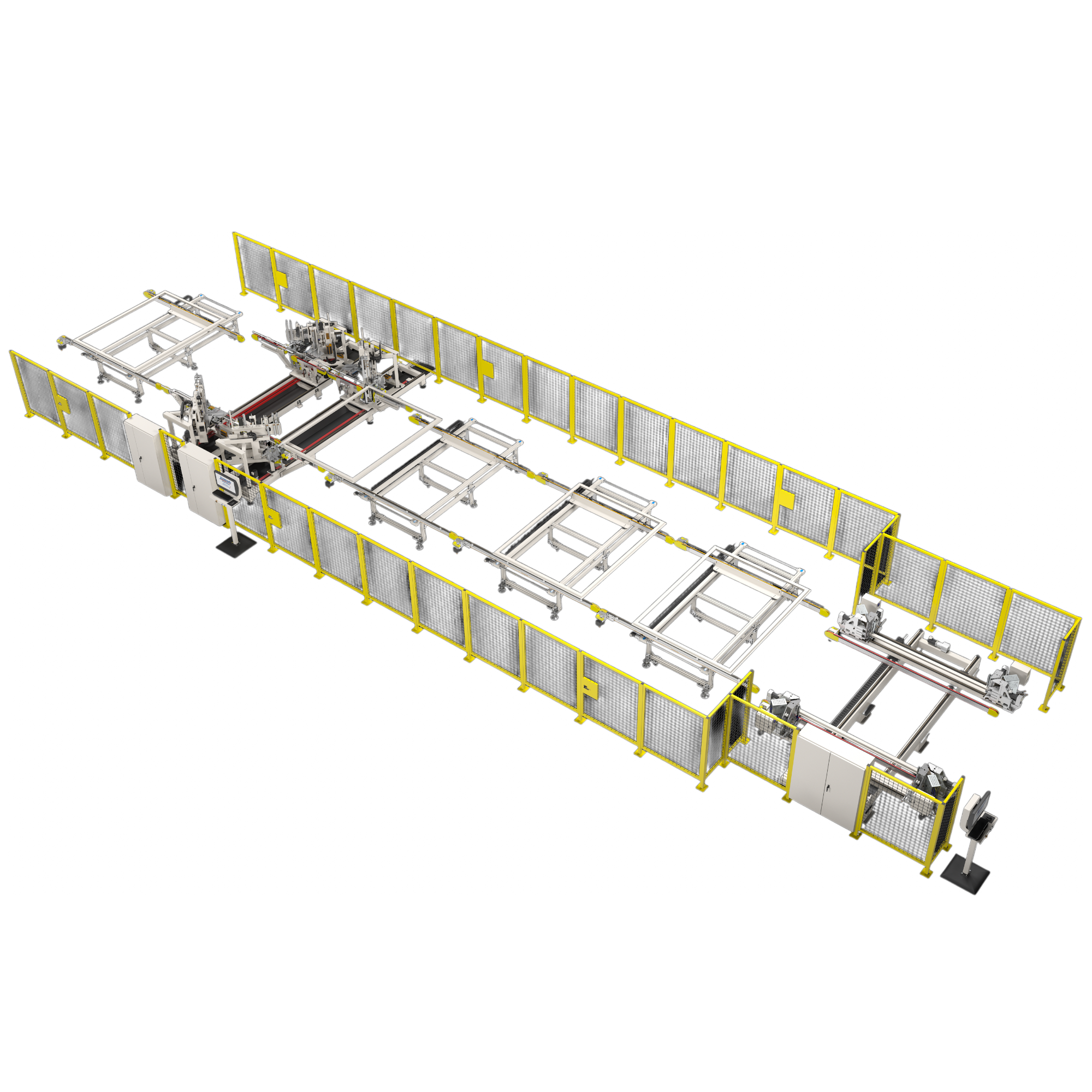

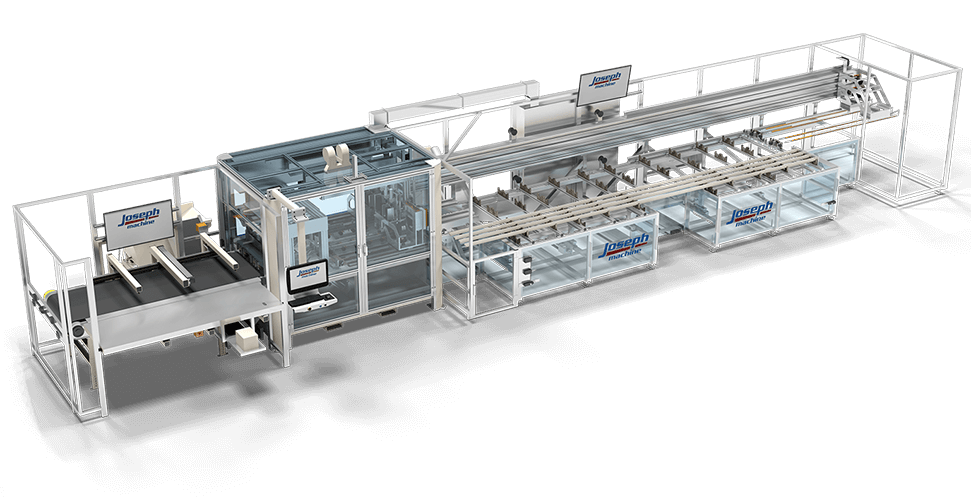

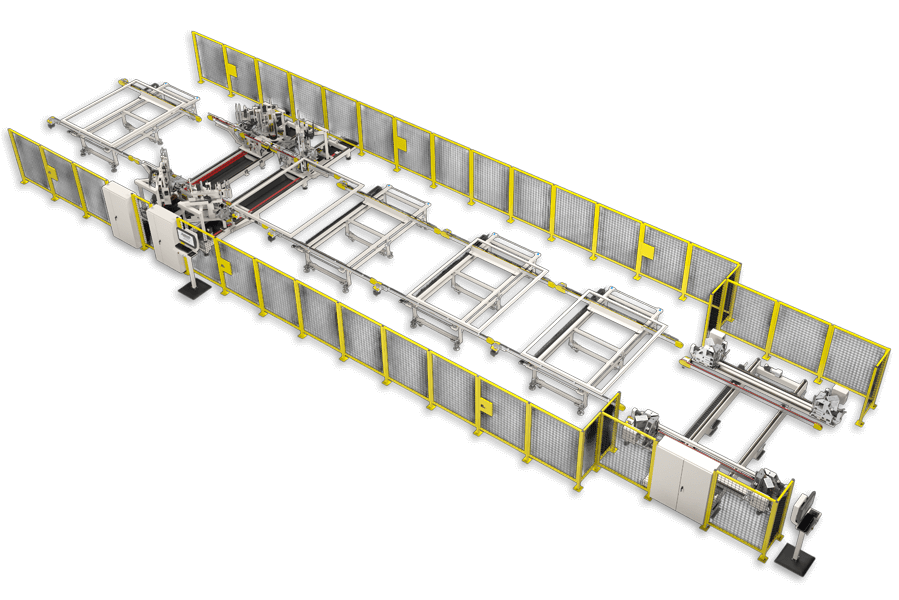

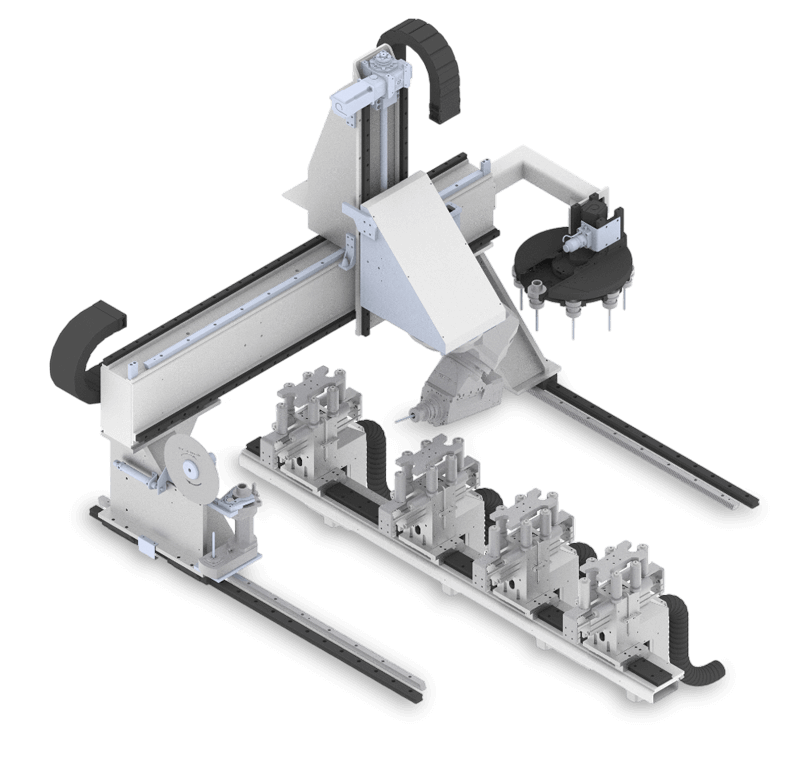

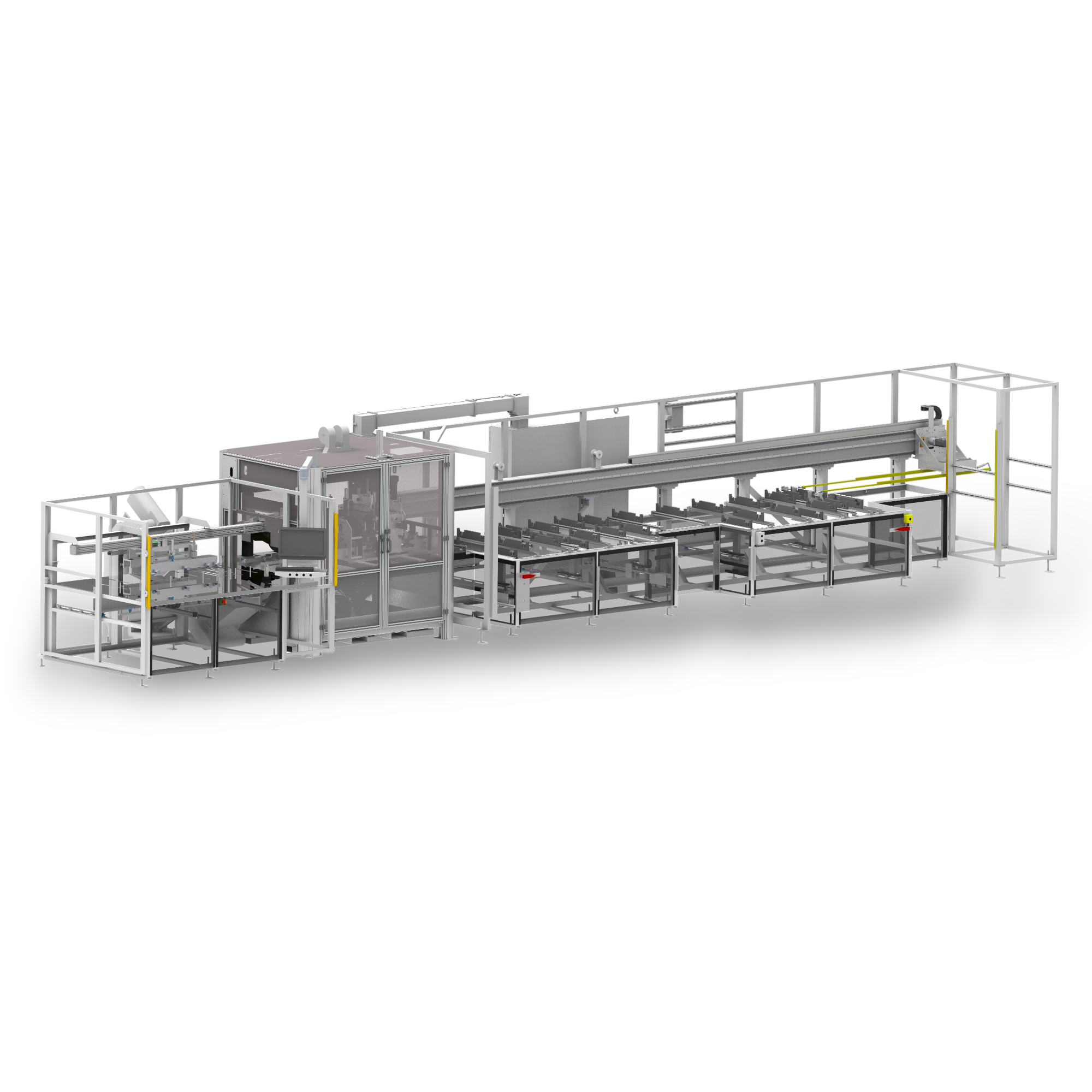

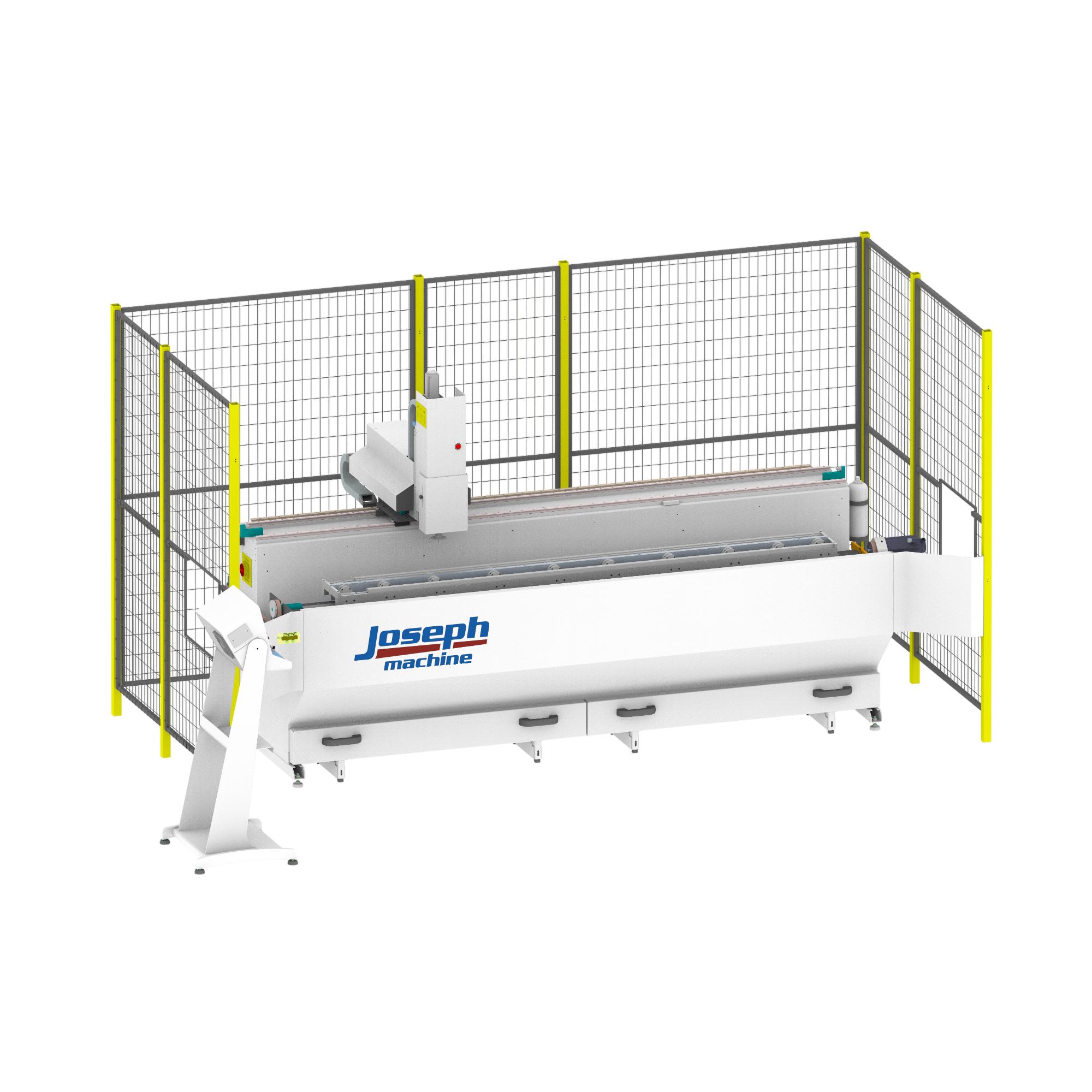

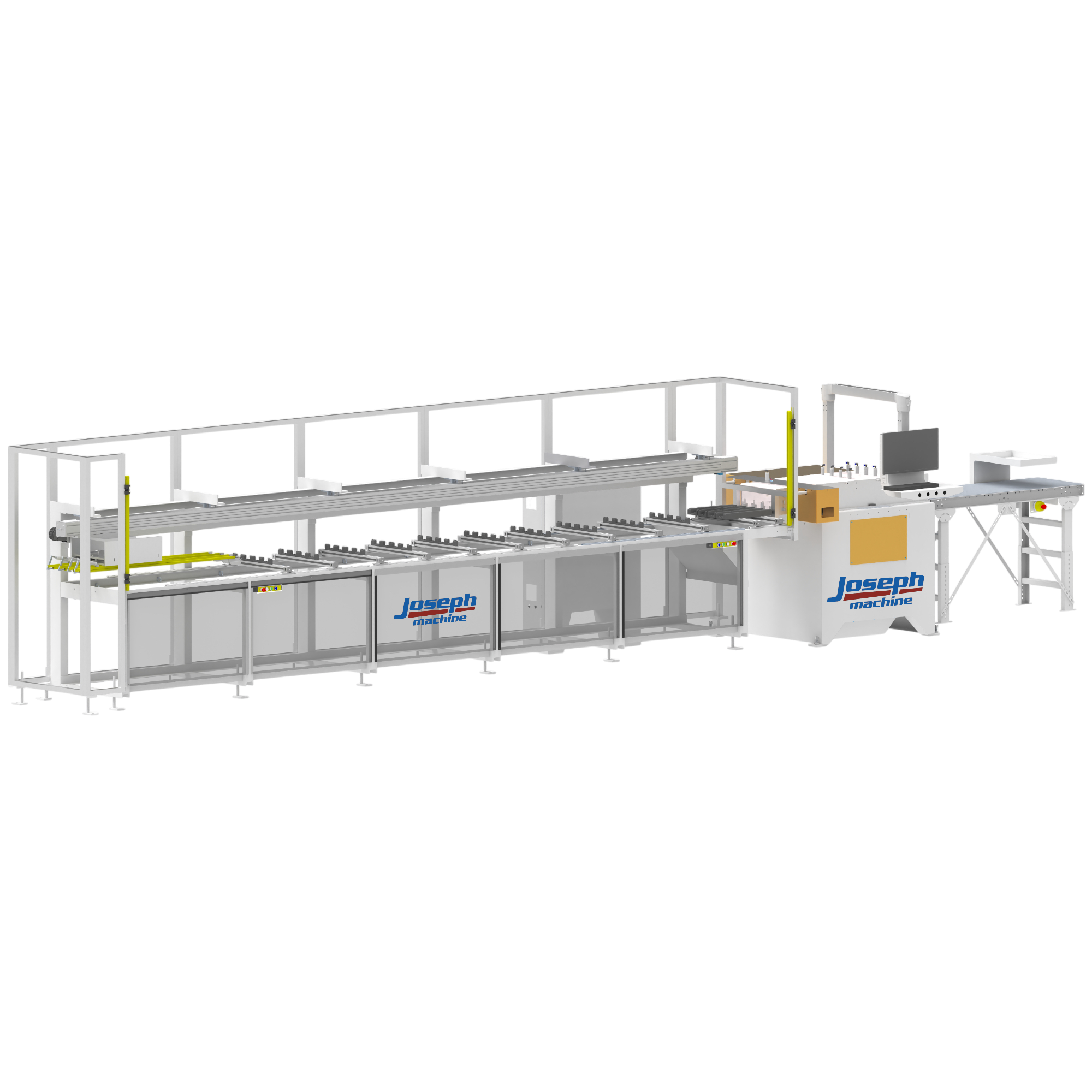

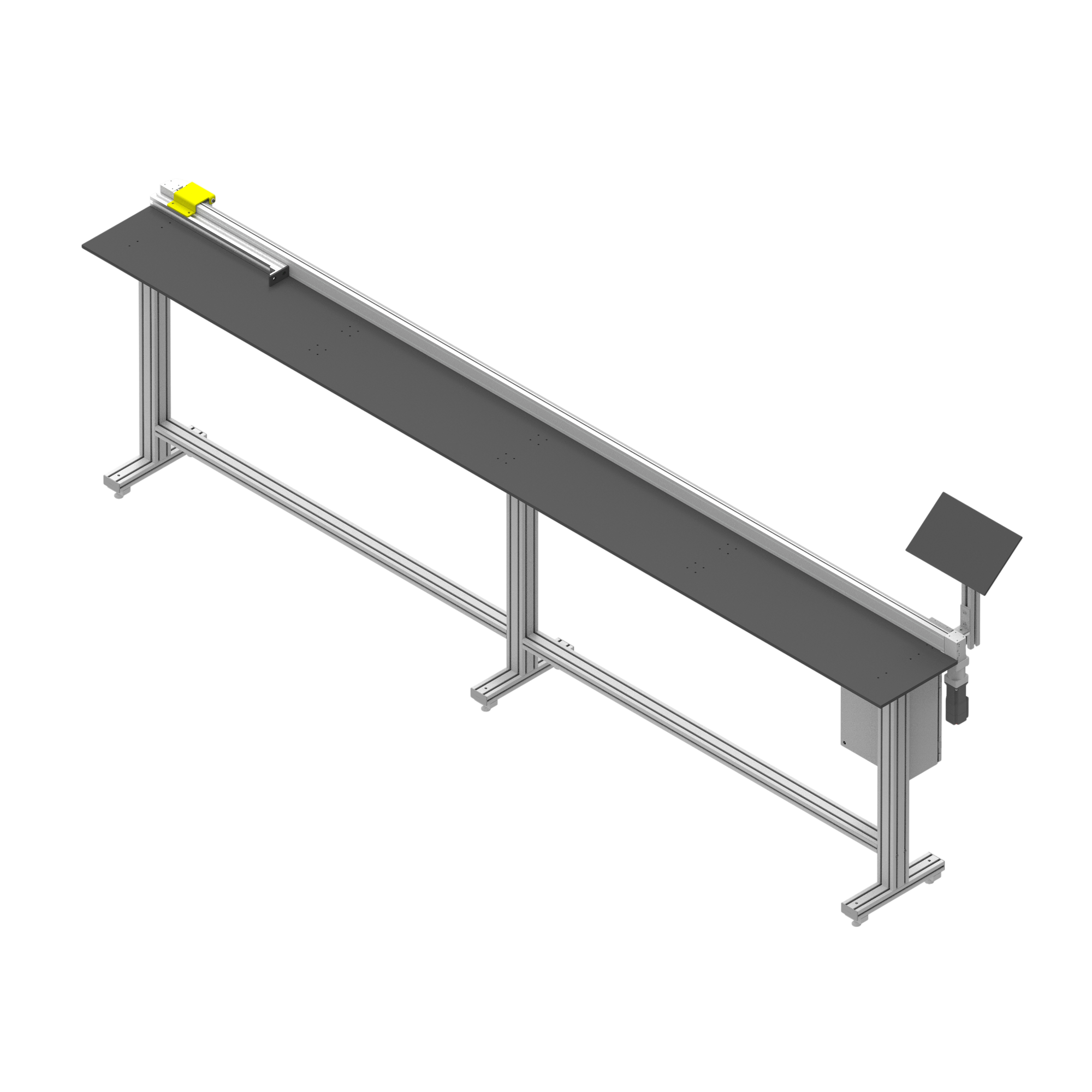

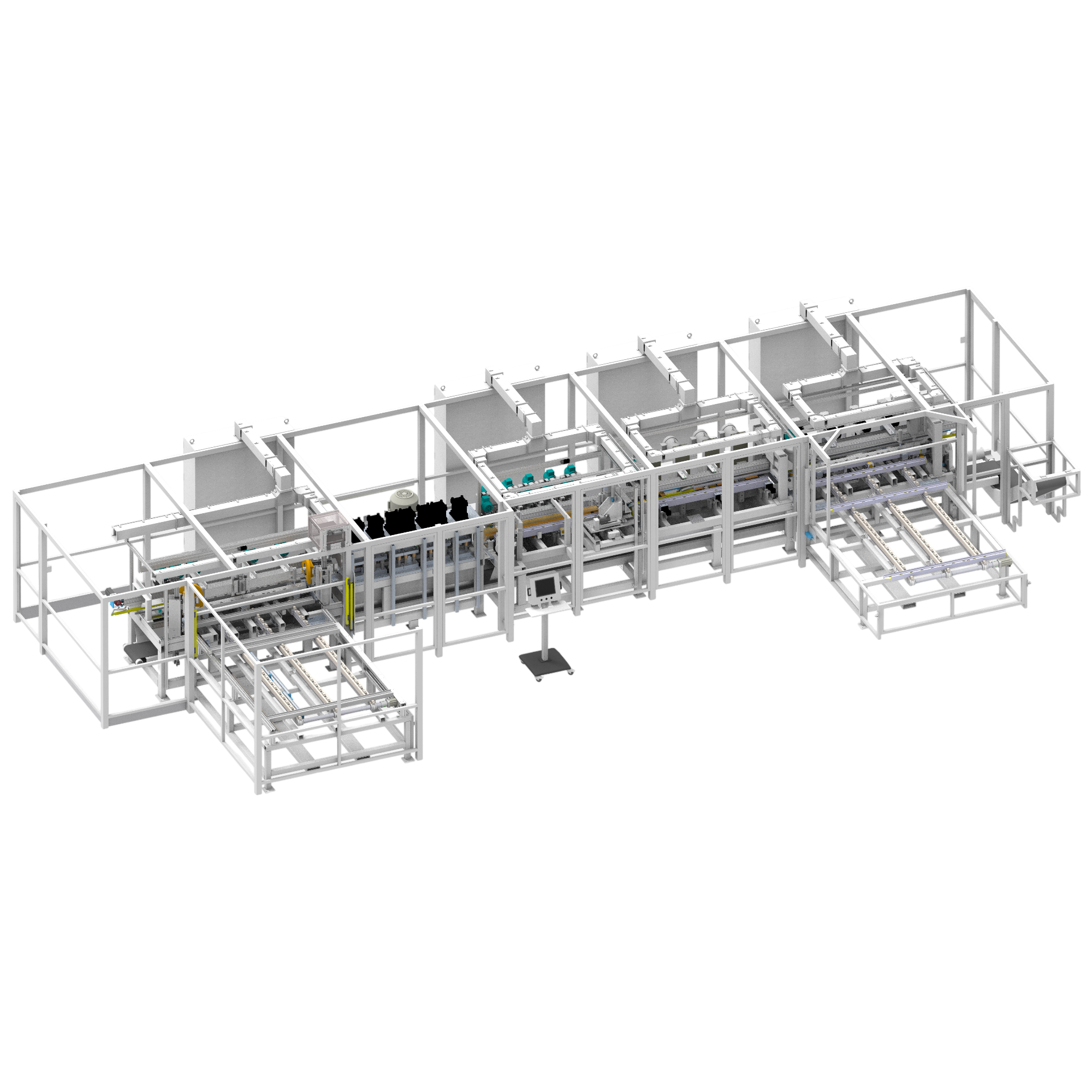

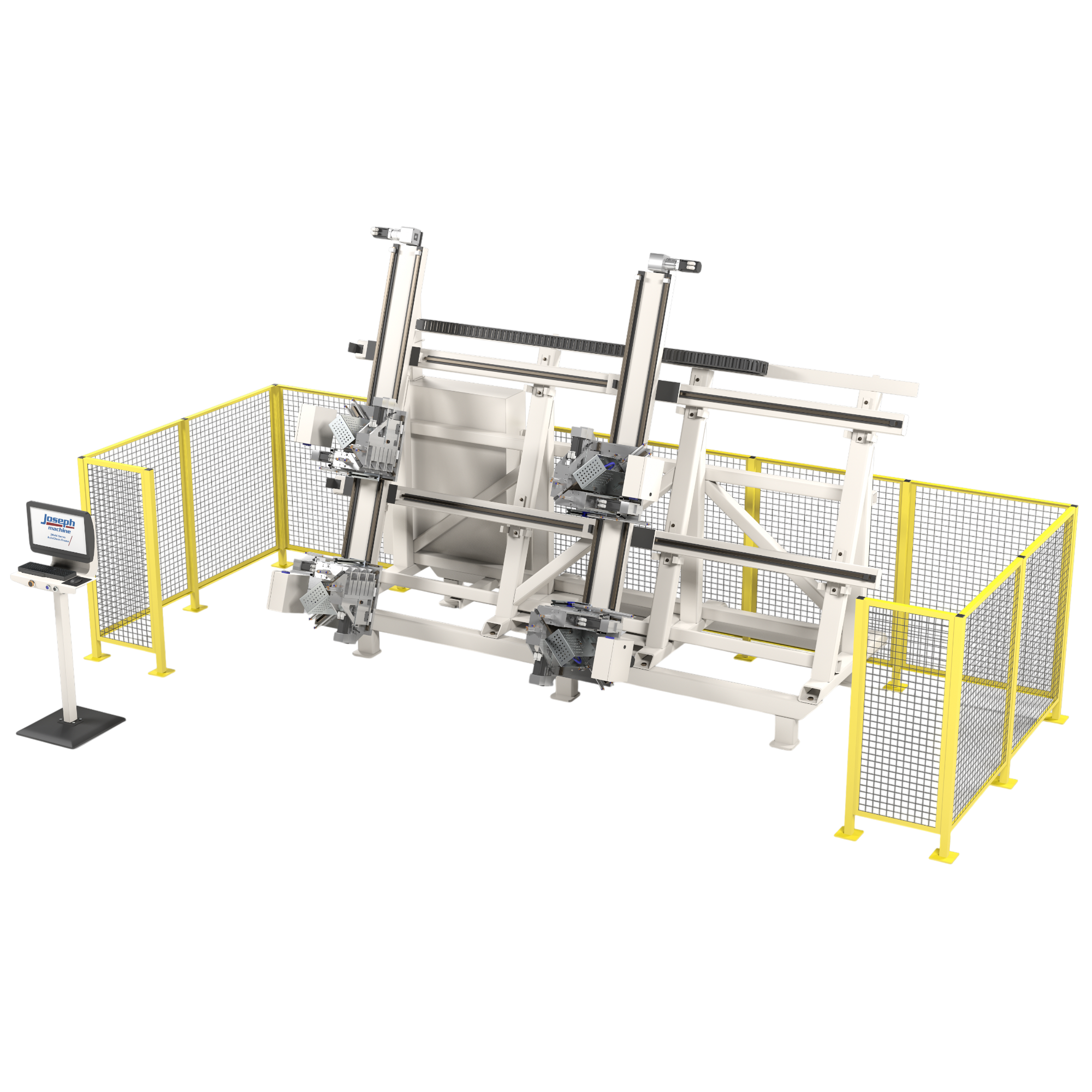

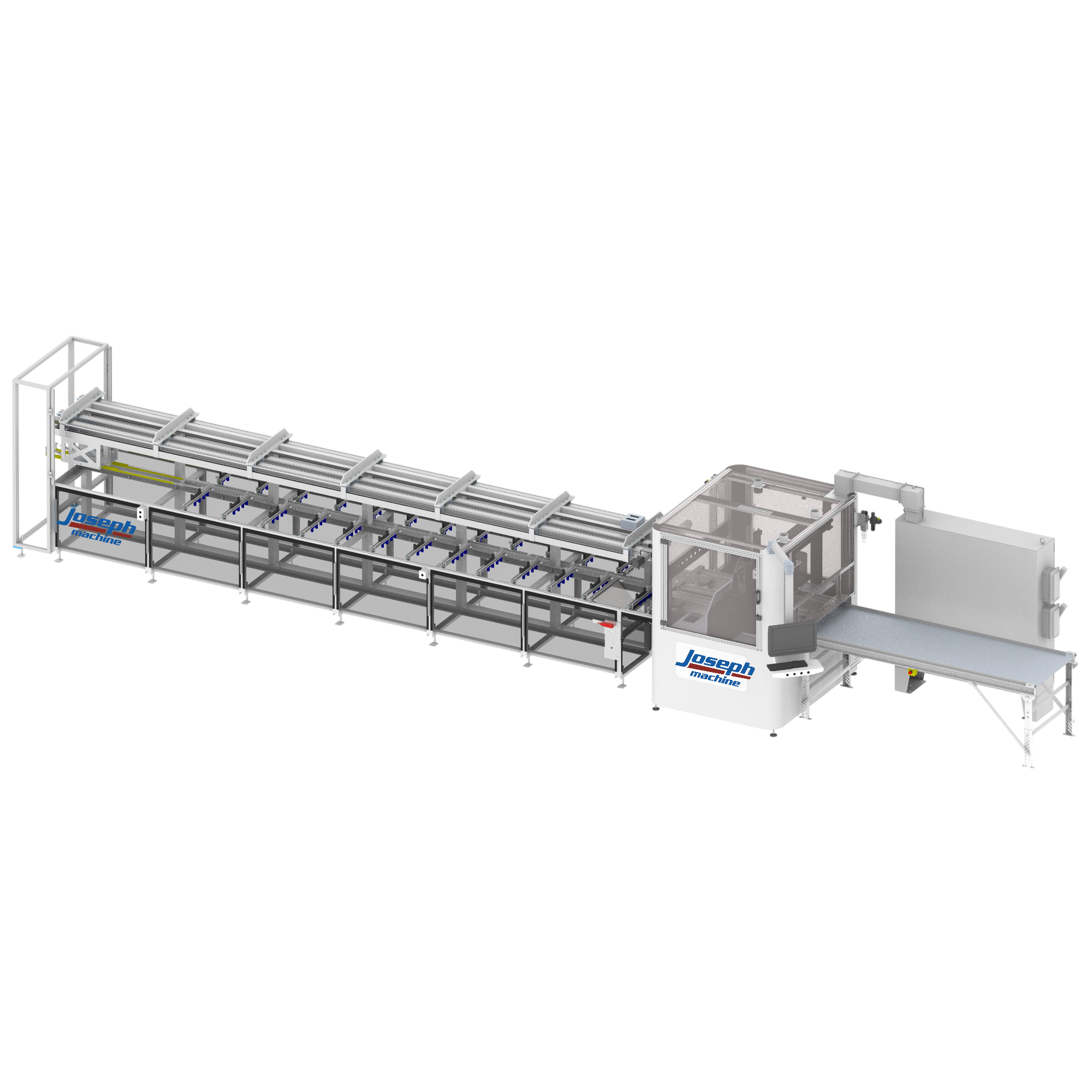

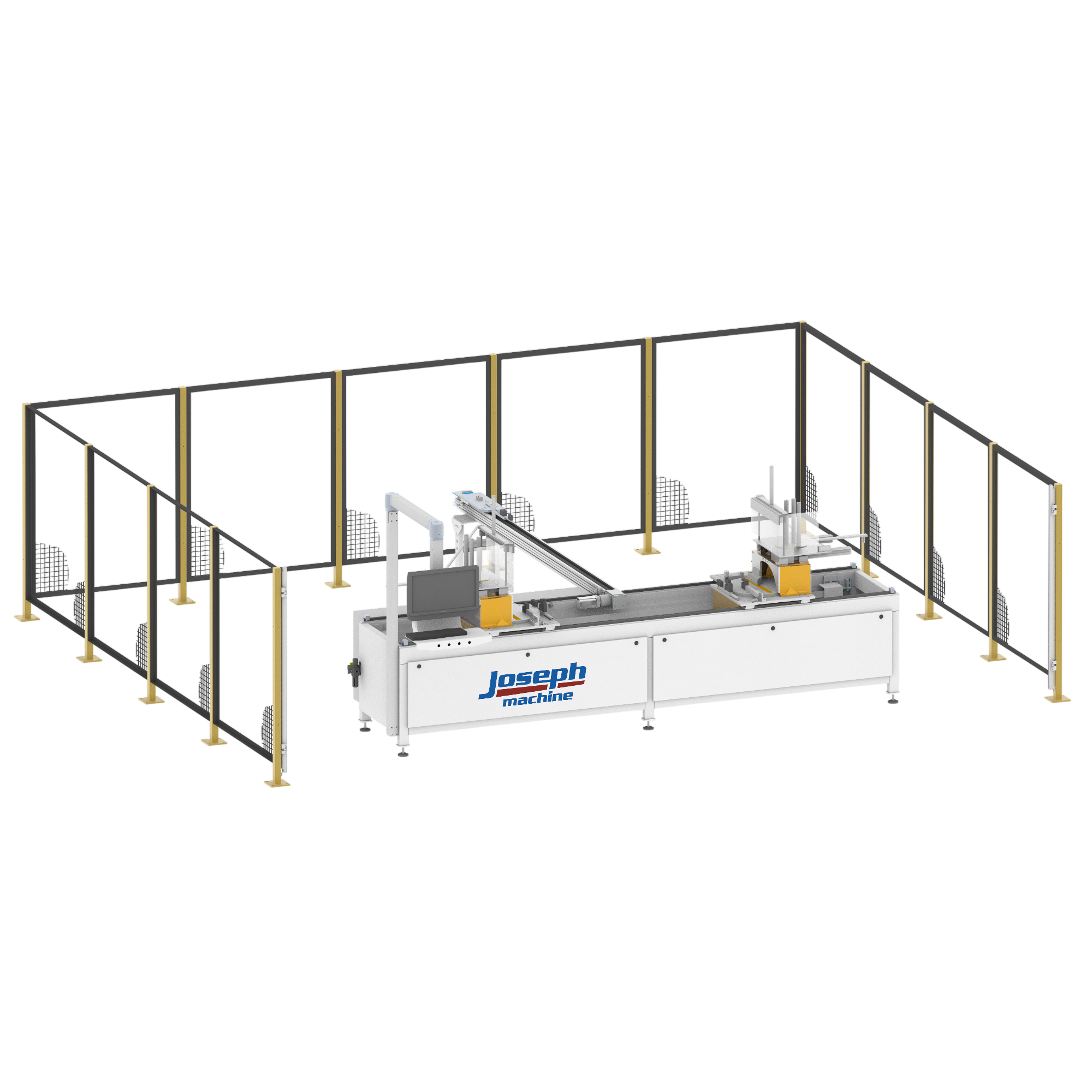

Equipment for cutting and fabricating extruded material

Joseph Machine designs and builds CNC equipment purpose-built for cutting and fabricating extruded materials. Our systems combine multi-track processing, rigid mechanical design, and in-house controls and software to deliver predictable cycle times, high accuracy, and exceptional uptime. Every machine is engineered around real production constraints—so customers run faster, scrap less, and rely on equipment that performs day after day.

Equipment tailored to your exact needs

Give us your desired specs and production goals. Our expert engineers will provide the system you need now and help keep it up to date as your operation changes.