application type

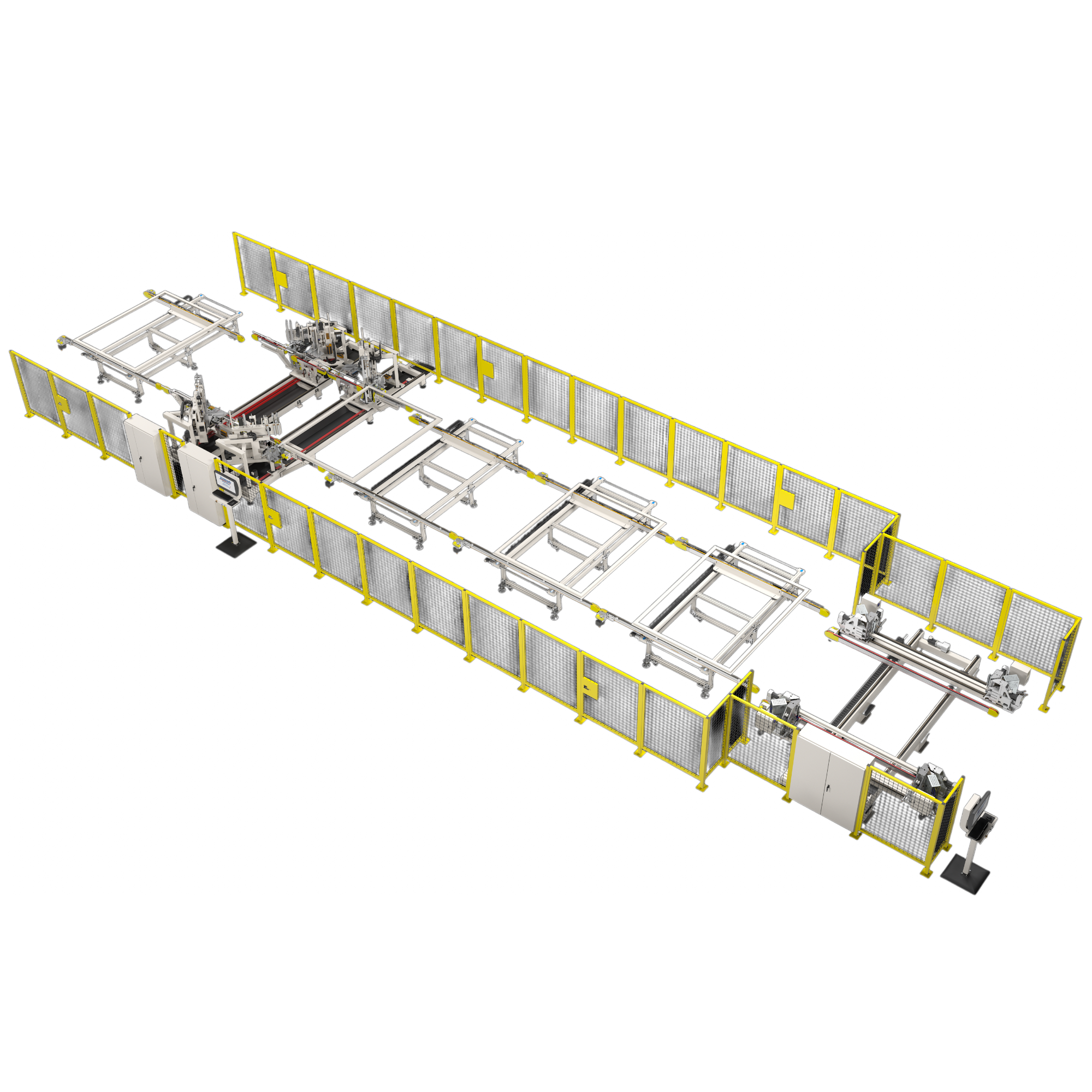

Hardware Assembly Automation

hardware assembly automation

Reduce Labor and Improve Precision in Hardware Insertion & Fastening

At Joseph Machine, we engineer hardware assembly automation systems that streamline the insertion, fastening, and alignment of key components — from hinges and locks to corner keys, brackets, and reinforcements. These workcells are widely used in the window and door industry, as well as in fencing, trailer, and enclosure manufacturing.

Hardware Assembly Machine Features

- Multi-head screw driving stations with torque monitoring

- Intelligent part sensing for error-proofed assembly

- Auto-feeding fasteners to reduce manual handling

- Custom pneumatic or servo-actuated tooling for varied part profiles

- Optional barcode/vision confirmation systems

We offer both standalone workcells and integrated final assembly lines that include pre-drilling, alignment, insertion, and quality validation.

Value to Fabricators

- Reduce Repetitive Labor: Eliminate time-consuming fastening tasks with single-operator workcells

- Zero-Mistake Assembly: Machine-controlled process reduces human error

- Flexible Design: Easily retooled for new part geometries or profile changes

- Fast ROI: Dramatic improvement in cycle time and throughput

From small-batch producers to multi-line operations, our hardware automation platforms are tailored to meet your production volumes and complexity.

Equipment tailored to your exact needs

Give us your desired specs and production goals. Our expert engineers will provide the system you need now and help keep it up to date as your operation changes.