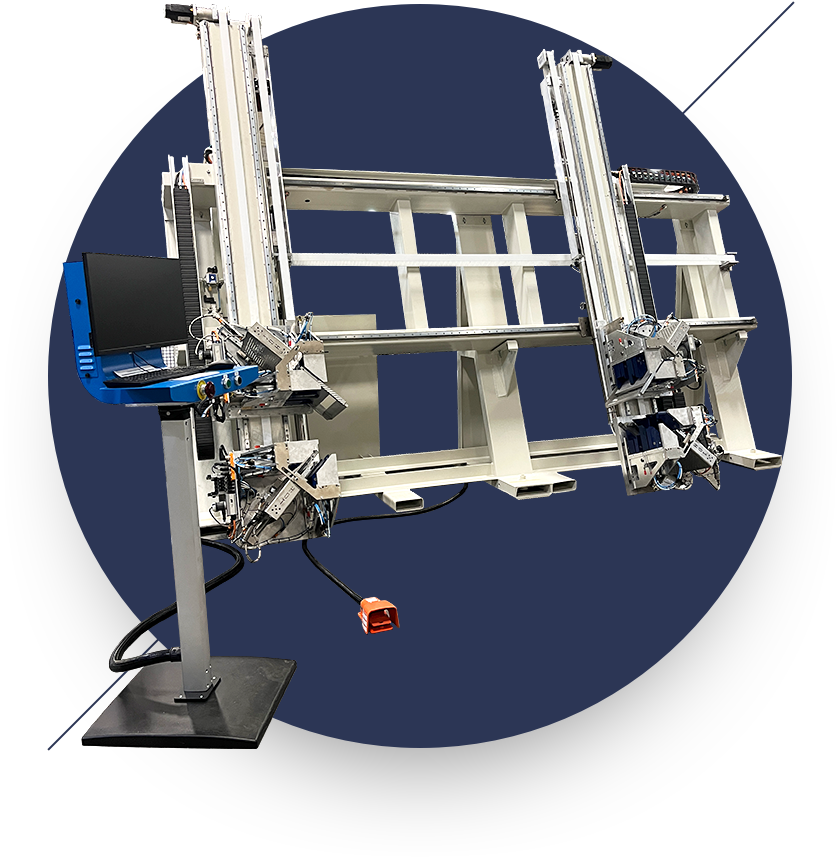

Industry Leading PVC Welding and Cleaning Machines for Window & Door Fabrication

Set your operation apart with our full line of automated or manual systems that saves cycle time, increases throughput and produces an overall better product.

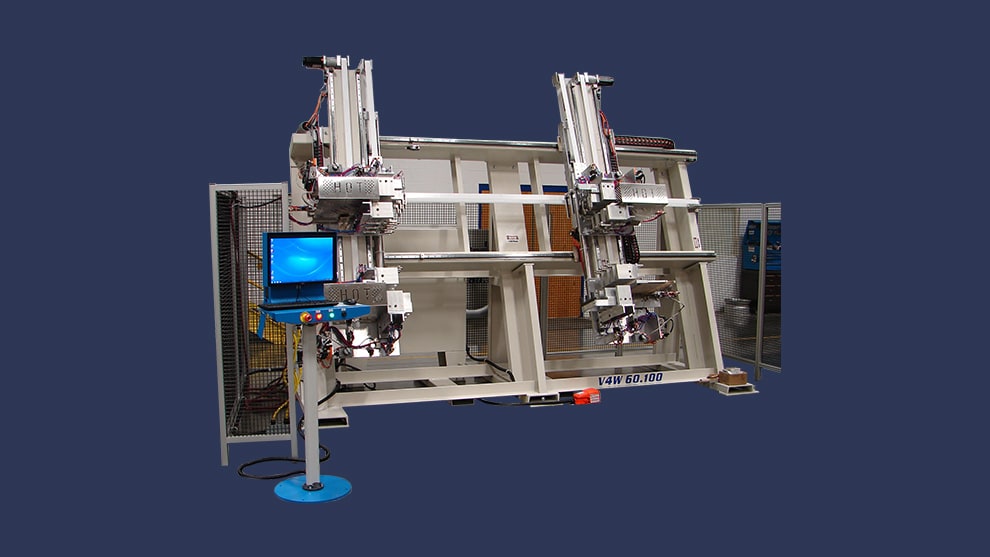

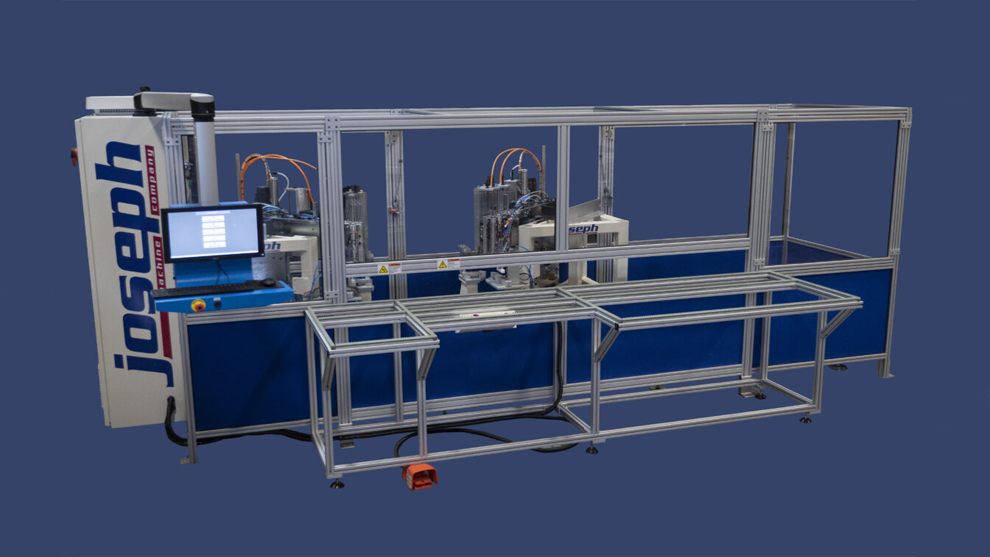

Joseph systems maximize repeatability, reliability and floor space. Operations with completely automated lines transfer windows directly from a welder to a cleaning machine. Create safer part transitions and need only one-fourth the labor requirements.

Need to add welding and cleaning capacity, increase throughput, optimize for single piece flow with a pass through line? Our engineers can help create the right system for your line.