Equipment isn’t cheap. And if you’re looking to invest in a new lineal extrusion processing line, you likely have a very specific goal for your plant.

Maybe you’re looking to cut cycle times, reduce remakes and increase uptime. Or perhaps you’ve spent weeks developing a detailed corporate engineering spec, and just need a machine that meets it.

That’s why we refuse to subscribe to a “catalog-only” sales mindset.

You already know what you need out of your equipment — and you need us to custom-engineer a machine that meets your exact requirements, not convince you to buy one of our existing machine platforms.

Here, we’ll show you what it’s like to partner with us to custom-engineer a lineal extrusion processing line, from the first time you call us until your lineal processing line is up, running and producing fully fabricated parts.

Every project starts with a conversation about your needs. We’ll ask the right questions and, more importantly, listen carefully to your answers.

Your answers will guide our decision-making during the equipment design stage, as we’re developing and refining your machine concept.

Armed with your answers and your specs, we’ll begin the design process.

Usually, we’ll spend a few days understanding your fabrication prints and analyzing your tolerance requirements (slot position, part length, miter angularity, etc.). Then, taking operational needs (cycle times, changeovers, etc.) into account, our application engineering team will design a custom machine concept.

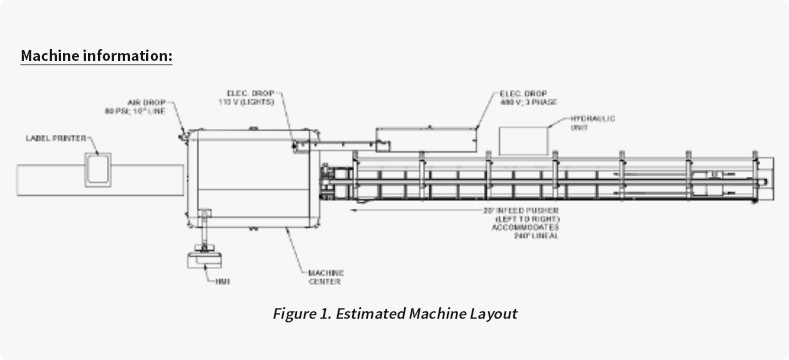

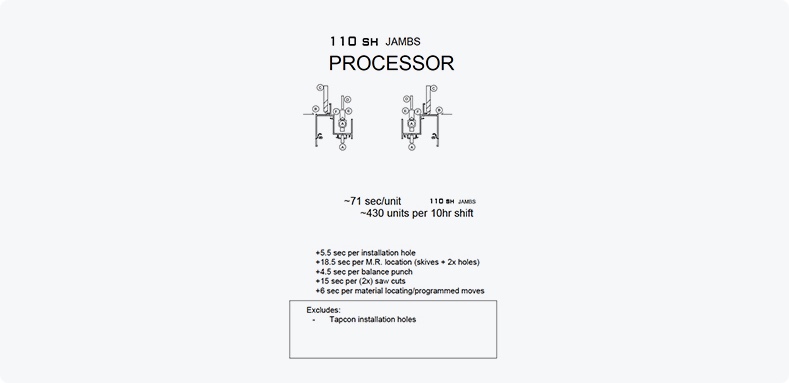

Here’s an example of a concept drawing we developed:

Notice that it calls out cycle time calculations, and clearly details any fabrication features that are not captured within the scope of the machine design.

We are always transparent as to what a particular design concept will and will not do, so you can make the most informed decisions. If a fabrication absolutely has to be done on this machine — and not secondarily — let us know, and we’ll do the work to make it happen.

Our initial concept details everything our application engineers learned you need from your machine during initial sales conversations.

But it’s just an opening offer. After we review the concept with you, the real custom-design process begins.

You may want to add, remove or change a feature we have called out in our concept. That’s absolutely fine — in fact, it’s encouraged. Our only goal is to design the just-right machine for your operations, and that often requires multiple design revisions.

Recently, we met with a client to review our concept — a two-track machining center that could cut and fabricate two aluminum parts at once. The client stated their daily throughput goals weren’t high enough to justify the addition of the second track. We altered the design according to their feedback, and they got a lower cost machine that better fit their needs.

We will refine and redesign your machine until it has all of what you need — and none of what you don’t.

It’s this iterative design process that ensures every company we work with squeezes as much productivity as possible from their machine, without spending a dime more than they need to.

Our team will send you a detailed quotation before you sign a purchase order.

Your quotation will include:

After you sign a purchase order, we will do the work to go from concept drawings to a real machine.

We deliver on-the-fly changes for customers all the time. Why? Because our priority is meeting your requirements — not selling from a catalog.

With a signed purchase order in hand, our applications team will develop your project’s Order Entry Checklist (OEC). The OEC combines all information — notes, documents, drawings — and combines it into one, comprehensive scope document.

Much like the blueprint for a construction project, your OEC defines exactly what you should expect from your finished machine. It’s the technical scope document we’ll use as our North Star throughout your machine build.

Once your OEC is created, our mechanical, controls and software engineering teams come together to ensure:

After we’ve verified internally that everything is in order, we’ll loop you in to present your OEC and get your signoff before commencing production.

You’ll be assigned a dedicated Project Manager, who will be your main point of contact throughout your machine build.

After being looped into your project, your PM will immediately do four things:

Verify your OEC — Your PM reviews your OEC with fresh eyes, identifying any conflicting or missing information. This is one of many quality control gateways baked into our custom-build process.

Generate an initial project timeline. This allows your team and ours to agree on tentative dates for key milestones including bill-of-material (BOM) releases, software reviews, factory acceptance testing and more. You can view a sample timeline here.

Set your project up in Basecamp. Basecamp, our secure project management system, is where we store all relevant documentation, updates and photos throughout your machine build.

Give you a full-access Basecamp login so you can monitor our progress every step of the way We give you real-time transparency into what we’re up to, and how we’re troubleshooting issues as they arise. You can also view photos and videos of your machine as it’s getting built.

Once the PM gets involved, they ensure the entire project runs smoothly — keeping everything on track and keeping you abreast of progress from start to finish.

Expect open and honest communication — we post everything to Basecamp, and you get to see it all.

Beyond regular Basecamp updates, your PM will check in with you weekly to answer any questions and make sure you’re up to speed.

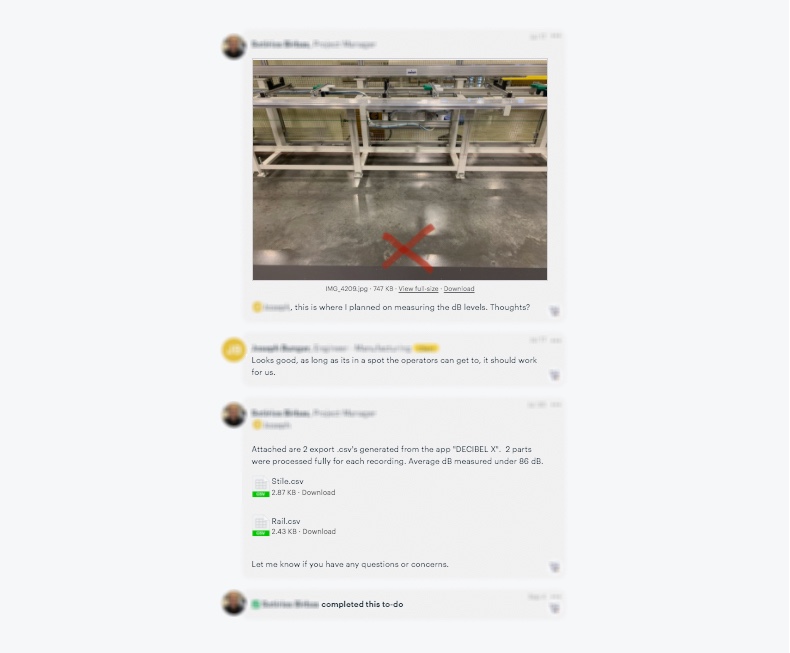

Conversations like the one below are common:

Your PM will walk you step by step through the process until your machine is built, and ready to be tested.

Any time an issue arises, your PM will delegate it to our ASAP team. The four-person ASAP team — composed of our directors of engineering, supply chain operations and service — collectively has decades of experience and will quickly map out the most effective way to address any problem.

This is the main event. You’ll come to our facility in Dillsburg, Pennsylvania for a week, and we’ll run your machine to ensure it exactly meets the qualification criteria outlined in your OEC.

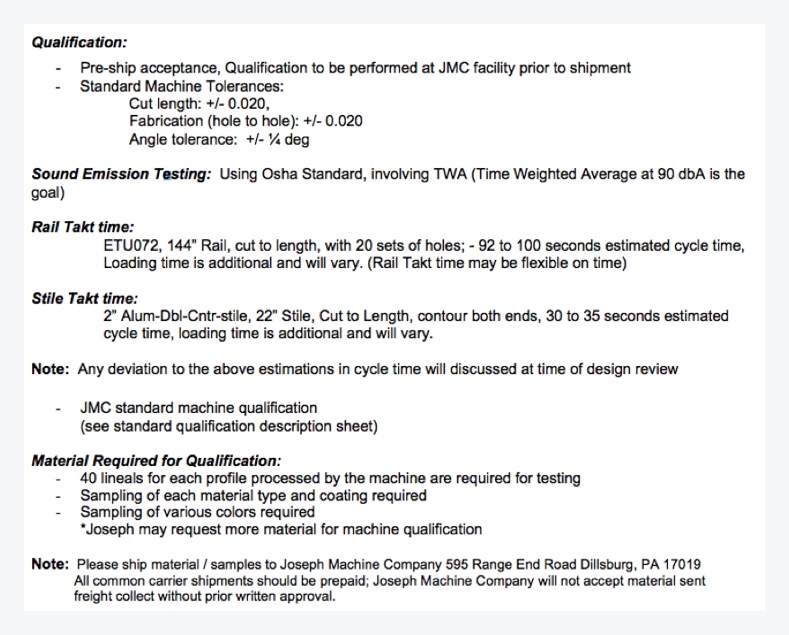

The qualification criteria are different for every customer, but often include fabrication tolerances, cycle time targets and cut length tolerances.

Here is an example of the criteria we used to test a lineal processing line we engineered for a high-end garage door manufacturer:

After the qualification testing, your PM will assign any follow-up items to the appropriate teams. Basically, they’ll take care of everything required to make sure your machine is plant-floor-ready before we ship it off.

Throughout the week, we encourage you to explore our facility and introduce yourself to our team.

After a week of testing and relationship building, our clients often leave our plant with many of our team members’ cell phone numbers — from the service technicians to the director of engineering and everyone in between.

Feel free to call any Joseph team member up whenever you have a question. Calling them on their direct line will allow you to solve challenges as quickly as possible, with the team member who can best answer your question.

We’ll take care of it all — installing your machine, training your operators, answering your maintenance technicians’ questions and more. Our service technicians will typically stay on site at least four days as your team gets acquainted with your new machine.

You’ll get access to all the standard product support offerings:

But Joseph’s client support philosophy goes far beyond “standard.”

We have a team of customer service representatives who proactively travel to our customers’ plants on a regular basis to do two things:

We don’t just wait for you to call us — we’re out there, traveling the country to diagnose and address issues before you have to pick up the phone.

Your success is our primary focus, from that first call until long after your machine has been installed.

We march to the beat of your drum. Let us know what we need to do on your lineal processing line, and we’ll make it happen.

Or, if you’d prefer to see a real-life example of our process, check out one of these three case studies:

Learn how a major curtain wall manufacturer automated their lineal processing line, and saw increased part quality, material yield and profit as a result. ...

Major manufacturer equips new facility with automatic system to make a window per minute...

See how Joseph Machine customized the perfect automated extrusion fabrication system for a major automotive aluminum supplier...