The “skilled labor gap” isn’t some nebulous concept or market trend to the window manufacturers and extruders we work with. It’s a very real problem impacting the profitability of their production lines — you can’t, after all, operate equipment without operators.

As one fenestration client told us, “I hired 10 guys last week, two showed up for work and they both left by the end of the week.”

The labor pool is scarce, training is time-consuming and retention is low — so it makes sense that labor reduction is often used as the chief reason for exploring automated lineal processing solutions. Going from eight operators to just one is an extremely appealing proposition.

But when we’re working on a lineal processing automation solution, we take a hard stance on ROI:

The machine has to pay for itself in two to three years.

And when you run the numbers, labor alone typically doesn’t offset the upfront cost of lineal processing automation in such a quick time frame.

To neutralize the upfront investment within three years, you also have to factor in:

Quality and consistency — How many parts are you throwing out per shift due to operator (human) error?

Output — Could you be making more parts (and profit) per shift?

Efficiency — How much material are you losing to scrap? How much money are you losing to unplanned downtime?

It’s not that labor isn’t an important factor in why you should move to automation. It’s that you have to look deeper to see the true value of lineal processing automation across your plant’s operations.

Here, we’ll break down each of these automation justifications one by one: Labor, quality, output and efficiency.Automation can be a gamechanger for your operations, but it doesn’t make sense for every step in your production process.

Typically, we recommend against automation for parts that are very light, complex or don’t have the volume requirements to justify automation. For example, you often can’t neutralize the upfront cost of automation for muntin bars or screen parts.

If you have a specific question about automation for your plant, just ask. We’re happy to walk you through the cost justification and, if it doesn’t make sense, we’ll tell you.

Labor, as mentioned above, is the door through which most window manufacturers enter the automation discussion. So let’s begin there.

In an automated production line, the software driving your machine makes all the logical decisions for the product: Where a certain fabrication goes, the order to produce parts that will yield the most material, verifying that parts meet your tolerance requirements.

Your operator simply loads a stick of material, presses a button, and the machine — which is engineered and programmed to produce any number of part recipes — pushes a fully finished part onto the outfeed table.

You’re usually looking at one operator for every pair of automated machines. Depending on the number of operators currently required, it’s easy to see how this can lead to massive operational savings for your plant.

One curtain wall manufacturer was able to go from 10 operators down to one by upgrading from manual to automated equipment.

This means thousands of dollars in savings from labor every day.

They were able to mill, drill, cut and fabricate their aluminum parts within one machine center — and all the operator had to do was load extrusions into the machine, and unload the assembly-ready parts.

And that’s a pretty standard scenario.

It’s important to note that automation rarely replaces jobs. The fact is that the current workforce isn’t robust enough to handle the number of hands-on production jobs in the fenestration industry. It’s why many struggle to fill their open positions.

Automation simply allows you to reallocate your existing workforce to more meaningful positions, like maintenance technicians or supervisors, that are easier to retain.

Simply put, automation helps you bridge the skilled labor gap, reducing the cost of recruiting, training and turnover.

Keeping workers safe is top of mind for many plant managers. Unsafe equipment not only threatens the wellbeing of your workforce, but it also opens up your company to unnecessary risk and liability.

Training and operator knowledge are the primary layers of defense for manual equipment. Automated equipment adds a few more layers.

At Joseph Machine, we work to protect the operator by design. This means standard features like infeed and outfeed light curtains, emergency stop buttons, enclosures and interlocking doors.

In addition, we take an even broader view. Senior Engineer Brad Good, when talking about a project for a major aluminum extruder said:

“Basically, we had to make it impossible for an operator to get into the machine and injure themselves in any way.”

To us, it’s less about including discrete features, and more about engineering an overall safe experience for the operator.

It’s easy to quantify the cost of a safety event. One injury alone could very well cost more than the entire automated production line in increased insurance costs and liability.

It’s harder to assign a number to keeping each of your people safe, ensuring they can go home to their families after each and every shift. The team at Joseph is committed to using automation to help make your operations as safe as possible.

A very high number of parts — 5, 6 sometimes even 10% — are thrown out due to quality issues before they get out the factory door. Or, at least that’s what we’ve found crunching numbers for scores of window manufacturers and extruders.

And each part you throw out is a part you can’t sell.

There are two ways automation helps to fix this problem:

Eliminating human error — As operator/machine interaction decreases, part quality increases.

Catching mistakes early — Flagging out-of-spec parts immediately eliminates the risk of spending valuable production time making fully finished — but non-functioning — products.

Window manufacturers are producing more lines of windows, with more features every year. This diverse product mix has pushed the envelope in terms of manufacturing complexity.

We’ve worked on lines that produce 56 different combinations for one particular type of window. For a human operator to produce that window on manual equipment, they have to measure the drill locations, fabrications and cut lengths for each part. Each step is done sequentially, and by hand.

There’s a lot of room for error.

Compare that to automated equipment, which is pre-programmed with the recipes for each individual part and can even algorithmically determine the order in which to produce them to minimize scrap and production time.

All of this leads to greater accuracy, fewer mistakes and less rework. The chances of parts being produced without a particular hole, or with an out-of-spec fabrication, drops significantly.

Watch Senior Applications Engineer Tom Vajdic describe how he engineered an automated solution geared toward increasing production quality for a curtain wall manufacturer:

Automated equipment is designed with various sensors that continually monitor the position of the part in the machine, giving the operator real-time information about whether a particular fabrication is — or isn’t — within tolerance.

When requested, we can even design systems that clearly mark out-of-spec parts as they come off the machine. One system we designed marked bad parts with red paint, allowing the operator to put them in a separate pile.

This provides value in several ways:

The result? You won’t ever be left with thousands of fully finished products that are missing a fabrication.

If you make more parts per shift, you make more money per shift, provided the parts you’ve made are within your tolerance requirements.

While semi-automatic equipment often provides the best pure throughput speeds, automatic equipment provides the best balance between quality and cycle time. Which, as established above, is an incredibly important balance to strike.

And you can meet some pretty tight cycle time requirements with automated lines:

Your plant uses time and material to make products. Doing things faster, or with less material, pads your margins on those products.

And the software that drives automated equipment allows your plant to make more efficient use of its raw material (aluminum, wood, vinyl lineals) and production time.

Here’s how:

Lineal optimization software runs multiple algorithms to determine the production order for a given batch that will result in the least amount of scrap.

Basically, it allows you to make more parts with less material.

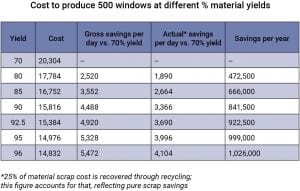

Even when plants recover a good portion of material cost through scrap recycling, increasing material yield by even a few percentage points can result in huge savings:

One of our clients calculated that his automated production line would pay for itself in 16 months based on scrap reduction alone — not even factoring in labor, output and quality.

“Unplanned downtime” is a four-letter word to window manufacturers and extruders. Nothing is worse than a machine failing in the middle of a production cycle.

We can install tool counters on all key components — drill bits, saw blades, etc. — which track wear, and alert your operator when it’s time to key to replace each part. This allows you to take care of maintenance activities before component wear leads to costly downtime.

Justifying automation isn’t just about running numbers in a spreadsheet, or considering the value of an throughput increase in theory — it’s about proving it in the field.

And to ensure you see the bottom-line improvement from your investment in automation, you’ll need to work with an equipment supplier that will customize your machine to your plant’s exact operations and specifications.

To that end, we provide value in a variety of ways:

It’s this upfront work, and dedication to long-term client success, that allows our clients to experience real ROI on their automated production lines. And it’s also why we get so many repeat orders — clients know they can trust us to dial in on their exact production requirements and expectations.

Learn more about working with our team on a custom machine build here.

Saving on labor is just the beginning. To see the full scope of what’s possible with automation, talk to our team today.