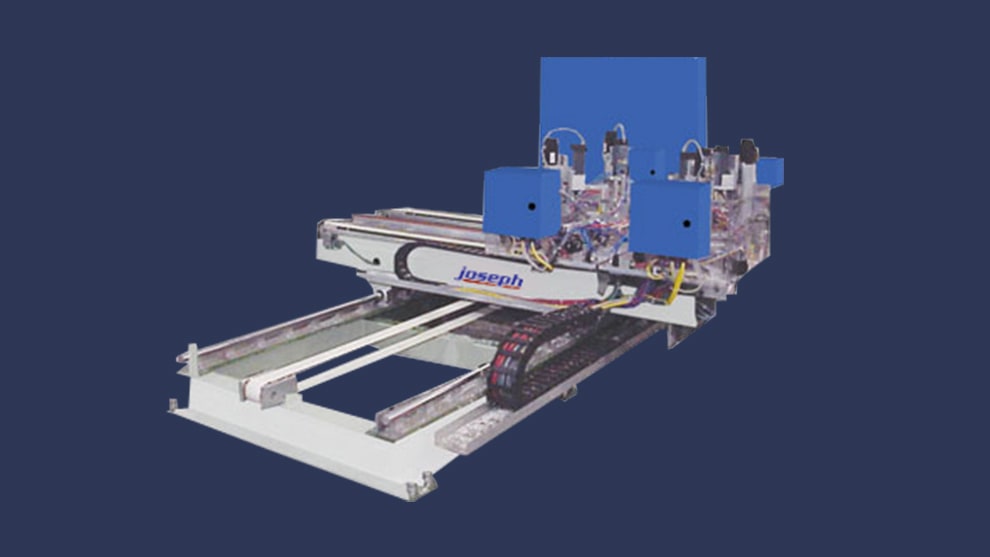

The Only PVC Welding and Cleaning Machine that Matters

Break away from complicated high-maintenance PVC welders and cleaners. Run faster with Joseph Machine’s line of automated or manual welding and cleaning machines.

At Joseph we make machines with one goal in mind: make more units faster and safer. This simple and reliable machine gets you more production from your floor space while using less labor.

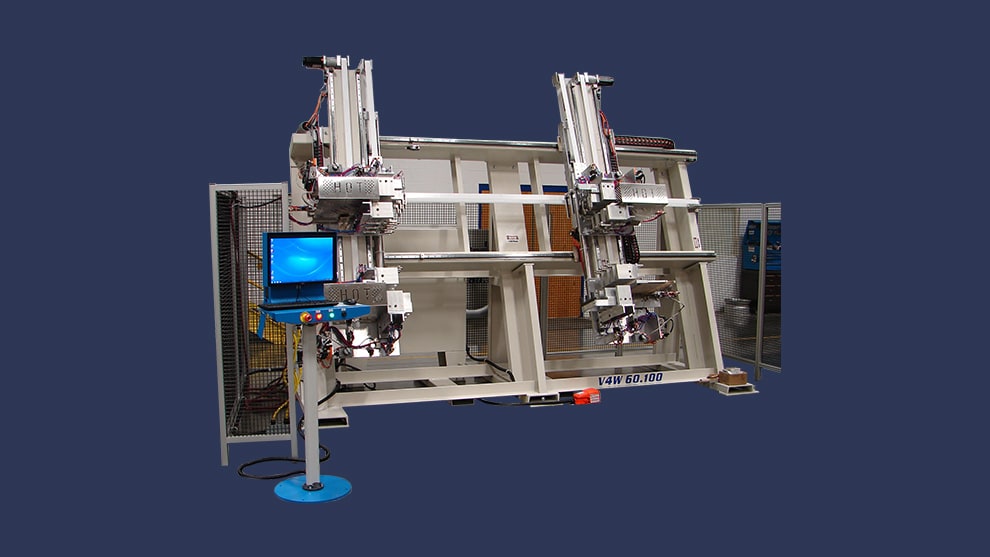

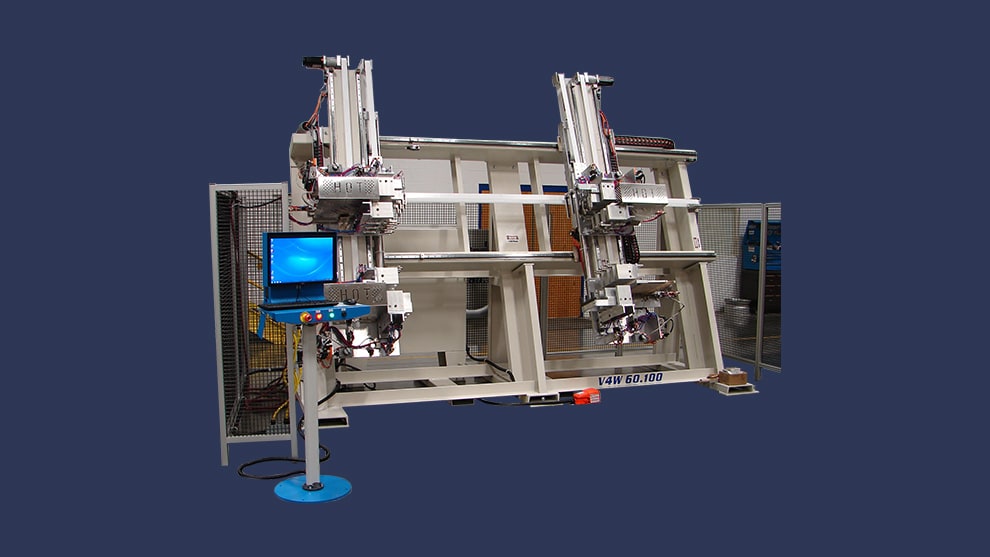

Double or quad-stacking capabilities let you use less people to make more product.

So simple your kids can use it. Push-button HMI lets you adjust sizing and custom fixtures on the fly.

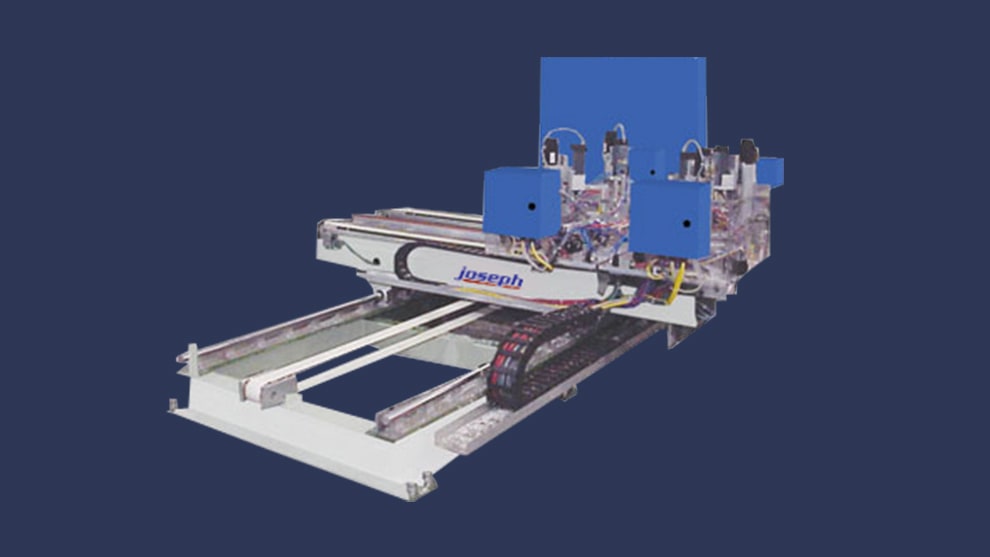

Completely automated systems transfers the job from welding to cleaning without manual labor.

The last PVC vinyl welder and cleaner you will ever need.

Make your vinyl welds faster and better without breaking your team’s back.

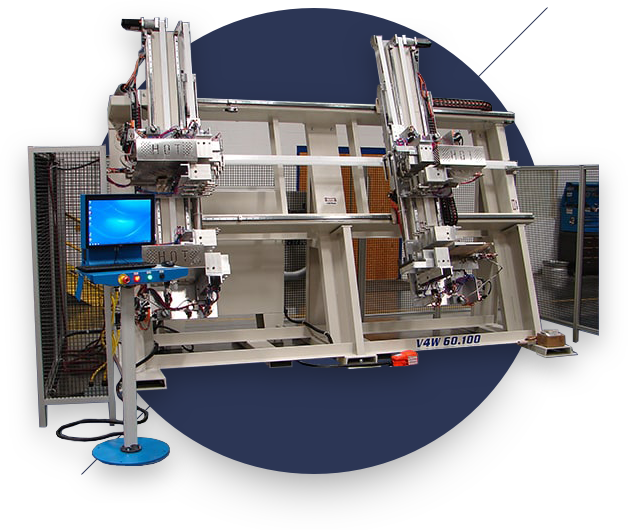

The fully automated automated V4W and H4W is loaded with feature after features designed to help your operation do one thing: dominate your market.

Weld up a window or door frame in 30 seconds. Do up to four windows in 60 seconds.

Easily make sizing adjustments with custom fixtures and an easy to use HMI interface.

Good work is hard to find. Get yourself a new helping hand that will produce for decades.

Joseph Machine’s vinyl welders and cleaners don’t just speed up production, they allow your people to do more difference-making work.

Lessen your reliance on manual labor where it doesn’t make a difference. Automate your vinyl welding and cleaning and put your team’s energy towards the jobs that matter most be that assembly, packaging, or prep.

Perform multiple jobs simultaneously. Quadruple your productivity using a single machine.

Stop letting the roadblocks of not having enough hands to do the work or machines that aren’t fast enough stop your operation from new contracts, new channels, and new markets.

Joseph Machines simultaneously clean, weld, and automatically transfer . You get to ramp production to exponential levels and leave your speed and quality challenges in the dust.