Establishing a partnership with your OEM to continually improve material yield requires work and diligence. But it can be a lucrative strategy for your company.

To see exactly how lucrative, let’s narrow in on a hypothetical example of a residential fenestration company manufacturing vinyl windows.

We need to make a few assumptions for this lineal material cost analysis:

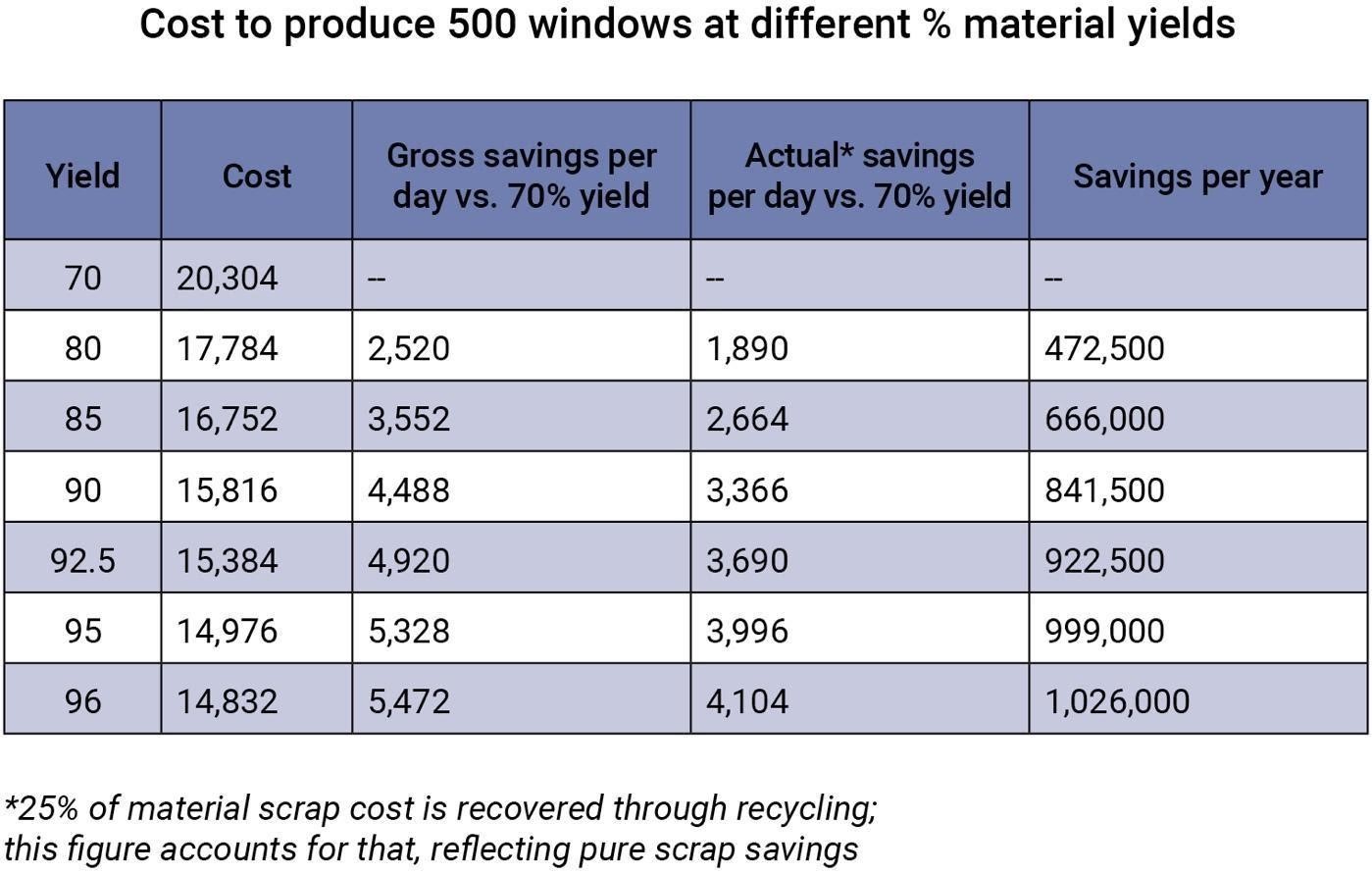

The key takeaway: For every 1% increase in material yield, you’ll see $27,000 in annual savings. And by making the jump from 70 to 90%, you’ll save $841,000 a year. Going to 95% will be hard work — but it’s worth almost a million a year.

For larger facilities, the savings are even bigger. A large residential fenestration client of ours reports that even a 0.1% increase in material yield is a gamechanger for them.

What could your company do with an extra $800,000 a year? Work with us to find out. And then let’s get to 95%.