Take a look at the bins, boxes and racks of partially used tail-end pieces throughout your facility. Every foot of scrap vinyl, aluminum or wood you see is cutting in your profit margins.

And while you can’t eliminate all scrap from the lineal cutting process, it’s well worth partnering with your equipment supplier to devise a proactive strategy that brings your scrap rate below 5%. If you don’t, you’re potentially leaving millions in operational expenses on the table.

In this article, we’ll walk you through:

There are two primary levers at your disposal to minimize scrap in the lineal cutting process:

And to break the 90% yield threshold, you need to have both the right equipment and the right software. Having only one in place won’t help you achieve your goal.

It doesn’t matter whether you have manual, semi-automatic or fully automatic lineal processing equipment — you need to pay attention to the design of your saw. And, more specifically, you need to ask your OEM how much lineal length is lost with each cut.

Every time a blade cuts, material is lost. When you consider a single part with two cuts, the amount of scrap produced by the saw might seem negligible. But it adds up over the course of a shift as you produce hundreds of parts. And over the course of a year, this lost length adds up to thousands of parts you couldn’t make and windows you couldn’t sell. It becomes a sizable operational loss with a real impact on your bottom line.

While a certain amount of waste from your saw is unavoidable, you shouldn’t accept a material yield lower than 99.5% when evaluating equipment.

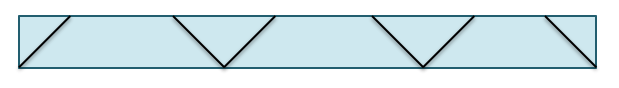

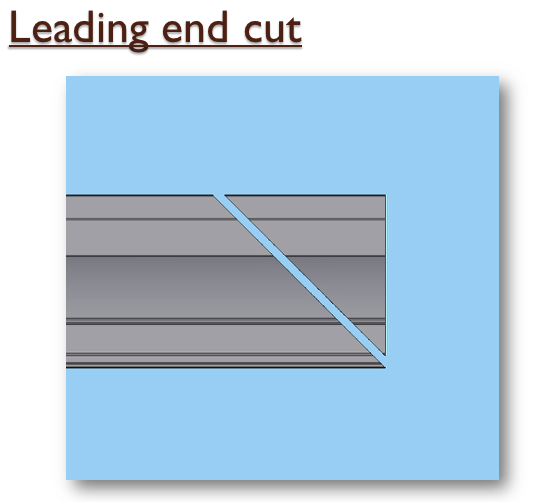

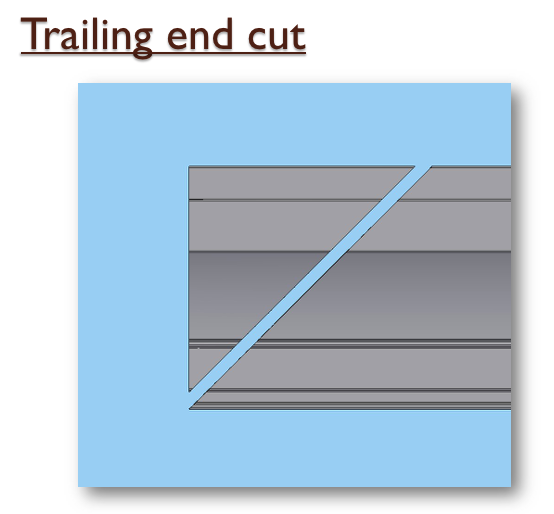

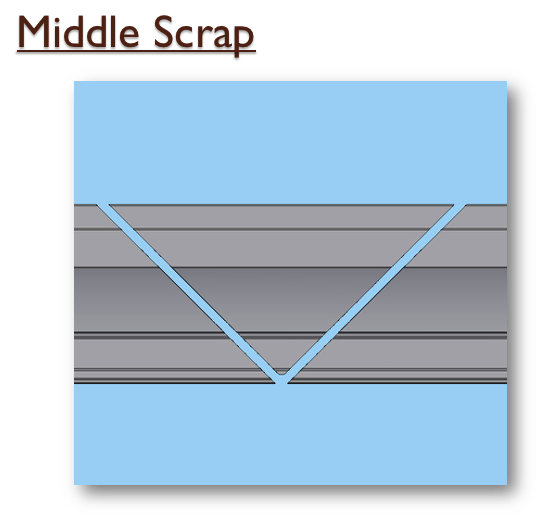

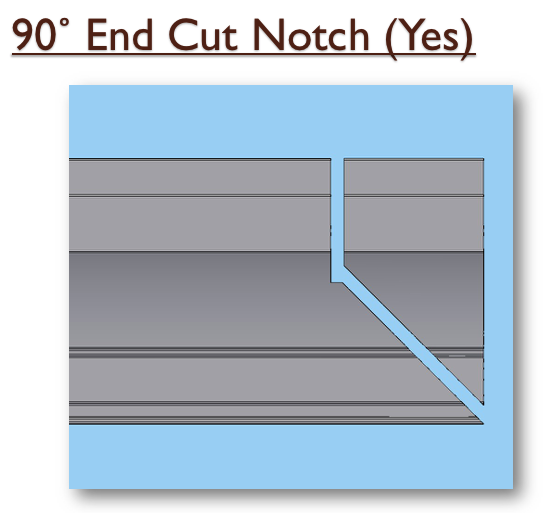

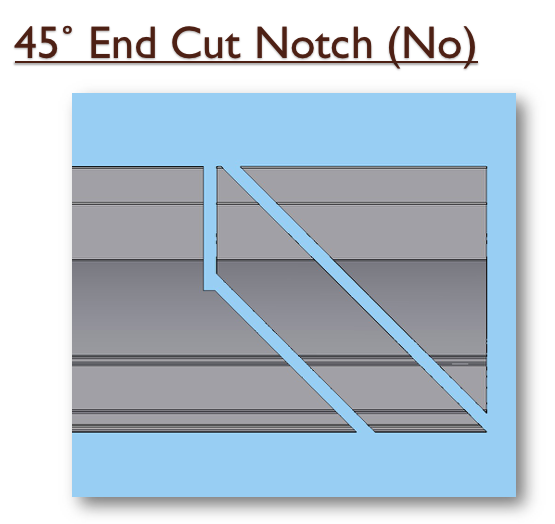

Say you’re cutting a part that has two 45-degree angle cuts:

A good saw design will be able to achieve zero scrap on the leading-edge cut, zero scrap on the trailing-edge cut and just one kerf (0.22 inches) of length lost in the middle cut. Most saws lose at least one kerf per cut — which results in more than double the scrap from cutting alone.

We released the first Zero-Scrap Technology for lineal processing almost 20 years ago. The key to our design was a custom gripper, paired with a saw which is oriented so that the inside surface of the blade meets the bottom point without taking any length off the lineal extrusion. When two middle cuts meet, the blade removes one kerf for both cuts.

You can also achieve a compound miter cut (pictured below) without losing any length on your lineal. Traditionally, you’d use an end head machine and lose two to three inches per cut. Over just one shift, this translates to more parts made and less scrap generated.

Many window manufacturers face a mathematical problem like this one on every shift: You have to produce a batch of 50 variable-length parts using fixed-length lineal extrusions.

No matter what order you choose to cut those parts, you’re going to have some tail-end scrap when the shift is finished. But some sequences will result in more scrap than others.

The question becomes:

How do you minimize the tail-end scrap while cutting all the parts you need?

Linear optimization software was engineered to give a clear answer to that question in mere seconds. It relies on algorithms that run your cut list and identify the part production sequence that will result in the least amount of scrap.

It defines the order in which you should make your parts, and the stick lengths (16, 20 or 22 feet) you should use to make them. The best sequence is populated in your dashboard and, once you sign off, you can cut your parts — confident that scrap will be kept to a minimum.

It’s easy to see how such an algorithmic approach would result in significant material savings over the traditional method of producing your cut list in order, scrapping any partially used tail ends.

Still, some software solutions are more robust than others.

See, each proprietary algorithm is slightly different, and there’s no silver bullet that will give you the best yield in every scenario.

What you want from your software provider is a system that runs multiple algorithms for each batch. Because no two algorithms will produce the exact same result, running several at once gives you a greater degree of certainty that you’re landing on the lowest-scrap sequence for your particular batch.

Multi-algorithm software can translate to a yield improvement of 2-3% over single-algorithm solutions, resulting in hundreds of thousands of dollars in opex savings depending on the size of your operation.

Over the years, we’ve developed three algorithms specifically designed to reduce scrap when cutting lineals to length. Each uses a different approach, and we’ve tested all three across hundreds of batches of data from customers. Sometimes, the first algorithm will provide the best yield; other times, the third algorithm will. Our software solution runs all three to ensure you get the best yield with every batch.

Theoretically, a zero-scrap saw and a strong lineal optimization solution should result in 90% material yield.

In fact, this theoretical yield is what many third-party software companies sell. They provide software that, if everything runs perfectly on your processing line, will give you 90% yield. And they attribute any discrepancy between this aspirational figure, and what you actually observe on the line, to your equipment.

But, as you know, nothing ever runs perfectly. Operators make errors, machines require maintenance and settings accidentally get changed.

This is why it’s so important to partner with an equipment supplier that also specializes in lineal optimization software.

They will take single-source responsibility for the effectiveness of both the equipment and software. And, ultimately, they will do the troubleshooting, education and work required to ensure that your actual yield is 90% — and that real-world savings follow.

And once you reach 90% yield, they’ll audit your processes to identify opportunities to get up to 95%, such as reducing remakes or defining the optimal batch size for your operation (bigger is better).

Establishing a partnership with your OEM to continually improve material yield requires work and diligence. But it can be a lucrative strategy for your company.

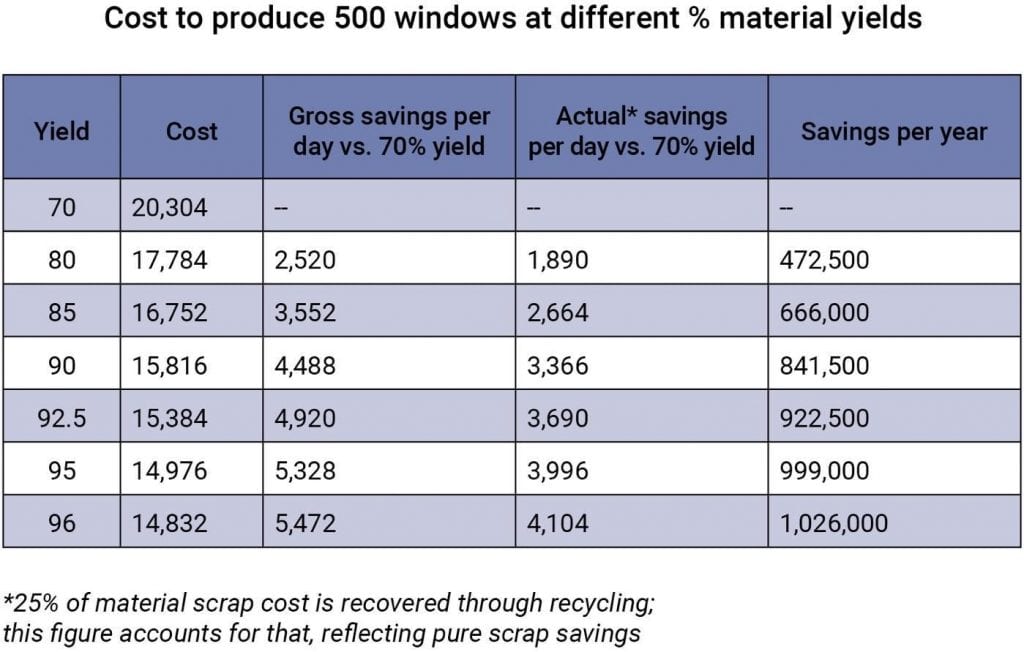

To see exactly how lucrative, let’s narrow in on a hypothetical example of a residential fenestration company manufacturing vinyl windows.

We’ll need to make a few assumptions for this lineal material cost analysis:

The key takeaway: For every 1% increase in material yield, you’ll see $27,000 in annual savings. And by making the jump from 70 to 90%, you’ll save $841,000 a year. Going to 95% will be hard work — but it’s worth almost a million a year.

For larger facilities, the savings are even bigger. A large residential fenestration client of ours reports that even a 0.1% increase in material yield is a gamechanger for them.

What could your company do with an extra $800,000 a year? Work with us to find out. And then let’s get to 95%.