A multi-million-dollar aluminum extruder needed an automatic system to fabricate 84” extruded rails that secure battery packs for a leading electric car manufacturer.

They needed a highly consistent system capable of operating around the clock to produce millions of parts with a 60-second cycle time — that’s about 480 parts per shift with no downtime.

And they knew who to turn to. The company previously worked with Joseph Machine to create several custom fabrication centers for aluminum automobile parts. So they called on their long-time partner in extrusion fabrication machinery to help solve this new challenge.

The system had to meet new demands while fitting within their existing floor plan. It had to maximize throughput with a reduced footprint and labor requirements while maintaining very tight quality tolerances. Manual labor could not fabricate quickly and accurately enough for their client’s needs and they had to look for new automatic solutions.

Joseph designed a line of fully automated, aluminum lineal fabrication machinery that has since created parts for more than 500,000 electric cars.

The customer also received the expert service and maintenance necessary to keep this system producing at peak levels, saving time and money with every cycle.

This project was very complex – the equipment had to meet extremely tight tolerances while producing a complete part every 60 seconds.

Despite these high hurdles, we began this project like we begin all others, with a discovery process defining simple guardrails:

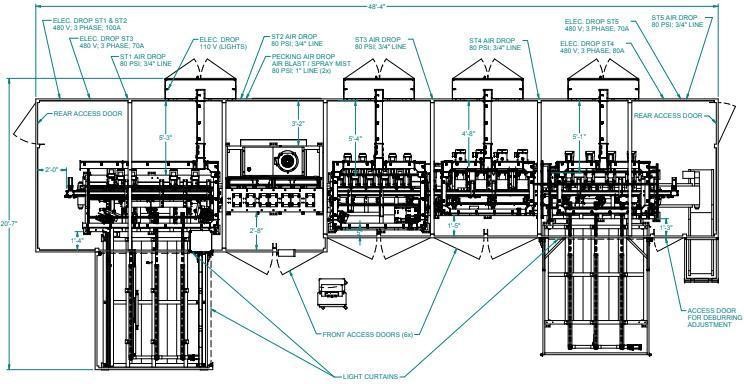

For this project, our engineers broke the manufacturing processes into five stages, arranging the sawing, drilling, routing and punching to create the fastest fabrication process possible.

Several concepts were created and shared with the client, with design reviews and refinements occurring until we found their ideal custom solution.

The auto manufacturer changed their specs several times throughout the process, and we changed our designs in turn.

Our designs addressed not just production needs, but work environment requirements as well. In initial designs, the machine footprint was square-shaped to minimize operator movement. However, that didn’t fit the client’s part handling process, so we elongated the design to roughly 20 feet wide and 48 feet long, which fit their operation while still keeping operator movements in an acceptable range.

Loading and unloading systems were arranged to handle 15 parts at a time with three operators — one on either side and another floating — which is half of the labor required for fully manual fabrication lines.

The client required comprehensive safety measures to ensure operator safety and prevent downtime. Safety interlocks were included on every access door and light curtains were added to the in- and out-feeds that stop the machine if disturbed while the conveyor belt is in motion.

Saw deburring brushes were added to keep the system producing perfect parts without adding downtime to service the blades.

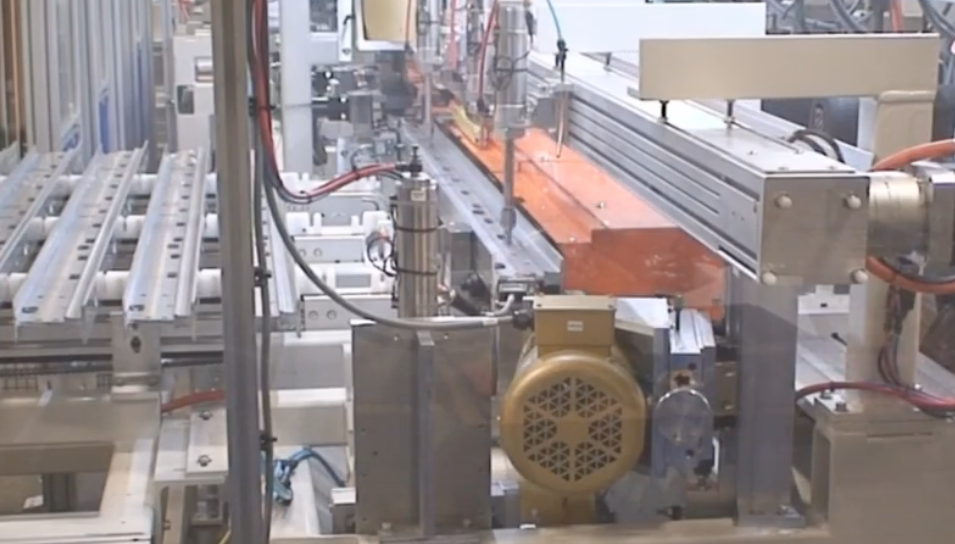

Preventative maintenance software was installed to help operators monitor sawblades and drill bits and schedule replacements, so they can predict unavoidable downtime and prevent potential failures. When service is required, the system is designed with large tool housing and access walkways for comfortable maintenance and repairs.

We also worked with the client to minimize waste through our Zero-Scrap Saw technology and lineal processing software. These methods can achieve up to 95% actual material yield, saving owners money in material waste and diminishing the time technicians spend handling faulty parts

The final design combined the functions of five machines into a single system capable of operating 24/7 while producing millions of parts under very tight tolerances.

The customer was involved throughout the design and build phases with access to our secure project management system so they could monitor our progress every step of the way.

The unit was tested at our facility in two shifts for over two weeks. Our team created thousands of parts to spec before the system was shipped, to ensure that once delivered, full production could immediately begin

And it still only took us eight months to deliver.

That’s one of the benefits of working with a small, nimble company that puts clients first, before and after purchase orders are signed.

What began as a single machine has grown into a line of three automatic fabrication systems that do the work of 26 CNC machines. They’ve already produced well over 500,000 parts and counting for one of the top car manufacturers in the world.

And we continue to improve these systems.

The first unit was in service for about a year when the client returned to work out some new ideas. We added a safe service mode that disabled all of the potentially hazardous components so technicians can safely and efficiently clean the system.

We’ve also transitioned from a fully mechanical clamping system to air gap sensors that maintain constant control of the lineal as it moves through the system for more precise fabrication and less material waste.

Parts that don’t meet tolerance standards are now rejected by the quality control system and marked with red paint. This eliminates the risk of a fully complete (but out-of-spec) assembly by removing it from the line after the first manufacturing process. Those faulty parts could have wasted 60 seconds a piece, along with labor and materials, if the problems weren’t caught until the last phase of production.

If your lineal fabrication operation isn’t meeting its potential, reach out to our expert engineers and find your tailor-made solution.

We’ll work closely with your team to ensure our product is perfect for your products, now and for years to come.